As part of your Design & Development, it is often necessary to produce prototype components. These can be used for Design Validation, fit and function testing, or to check their compatibility with associated mating parts. ZESAD can help you to make these first items and also develop a mass production procedure.

Prototype Services

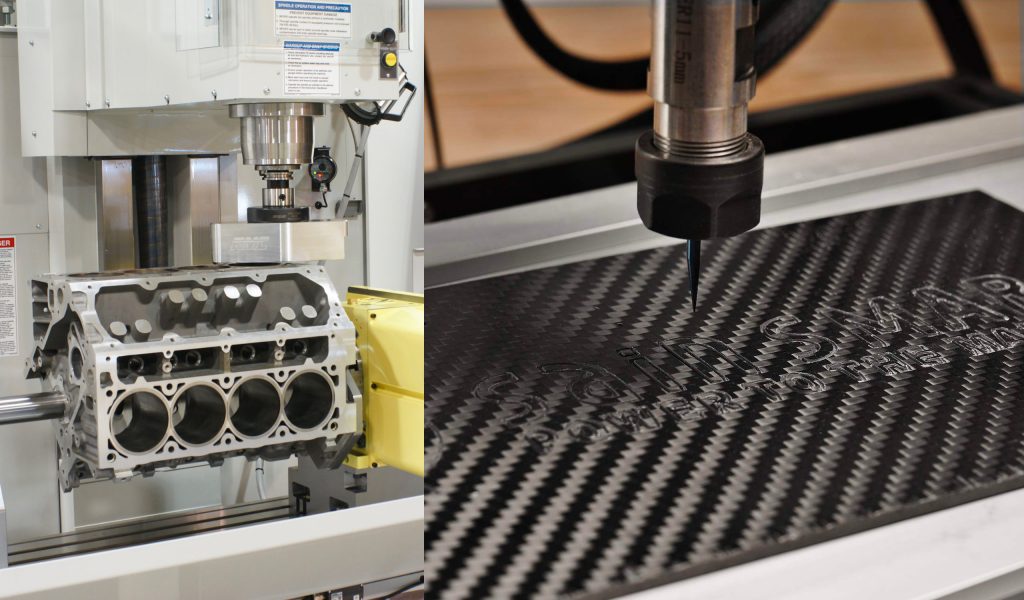

At ZESAD, we are able to design and fast produce prototype parts via both in our house capabilities and external partners who can cater for even more specialist materials or larger size components. If needed, we can also mass-produce the parts in a variety of materials when you are ready and have approved the prototypes.

ZESAD stands for Zentrale Entwicklungsgesellschaft Spezialisierten Automobilen Designs. That’s German for Central Development Company for Specialized Automotive Design. Our aim is to be your OEM / ODM manufacturing and development partner, for automotive related products. You concentrate on what you do best and let ZESAD handle the production & 3D design.

We operate Prototype shops both in Germany, as well as China, giving you the choice that matches your project and budget. Both shops are equipped to manufacture single single prototypes well as quantities up to small series and pre series quantities. Our components and materials had been certified according to TUV RHEINLAND product safety tests.

CNC Milling Aluminium with a variety of surface finishes

CNC Milling ABS in a variety of material colors

3D Printing with a variety of materials and surface finishes

We have also invested in a dedicated state of the art development moulding cell to allow us to explore, not only new production materials, their performance and aesthetics, but also how different materials might be combined within a design to enhance physical performance, lightweighting or recyclability.

Mass Production Options:

Carbon Fiber Autoclave cured in Prepeg or Forged Composite

PP Plastics, Injection Molded

ABS Plastics, Injection Molded

Together with partners, we have developed a number of new tooling concepts in specific areas to optimise aesthetic features such as surface finish and weld lines and in the area of weight saving we have a number of concepts that when correctly applied will show real and tangible gains to a components weight without compromising its recyclability.

These initiatives combined with many years’ experience in the areas such as Bi material and insert moulding means we are well equipped to support our customers to deliver hi tech solutions that meet the challenge of function, high performance whilst still optimising recyclability.

Carbon Fiber Autoclave:

Plastic Manufacturing Fields

ZESAD has invested in a variety of machines to accelerate our new product development activities, enabling an iterative approach that drives optimal and functional solutions before committing to tooling and assembly equipment. Parts of up to 356 x254 x 356 (mm) can be printed in production representative thermoplastic

materials including:

- PC

- PC/ABS

- ASA

- TPU Elastomer

In addition to deployment in new product design, an internal 3D printing service is now offered from our Leamington Spa Design Centre to our manufacturing plants, providing quick turn around in design and supply of Jigs, Fixtures, Assembly Aids and End of Arm Tooling to meet customer and programme needs.

Visit ZESAD.com for more details and technical engineering highlights!